SERVICES

Full service mold making from A to Z

With Adler you can rest assured a successful product launch due to the vast array of services offered across our network. From 3D printed prototypes to high cavitation class 101+ stack molds validated in-house and everything in-between, Adler ensures you total support in producing perfect parts every time.

Low Volume Molding

GMP certified molding operation including engineers trained in scientific molding,

an extensive inspection department, and a quality system designed for top tier production molding.

The molding facility is supported by a repair department and a full tooling facility making mold repairs

and revisions seamless to the end customer. Due to the complexity of the molds built and qualified, Adler

has acquired industry leading mold makers, tooling engineers, and process engineers to provide expert level

engineering making it an ideal molding facility. We have all you need in one location: Facilities, Equipment,

Process Engineers, Inspection Department, and the support of seasoned toolmakers.

Press sizes:

- 110 Ton Arburg

- 220 Ton Arburg

- 300 Ton Engel

- 135 Ton Haitian

- 289 Ton Nissei

- 110 Ton Toyo

- 500 Ton Toyo

Mold Design

In-house design using cutting-edge software ensures your vision is realized from the first part to the millionth part.

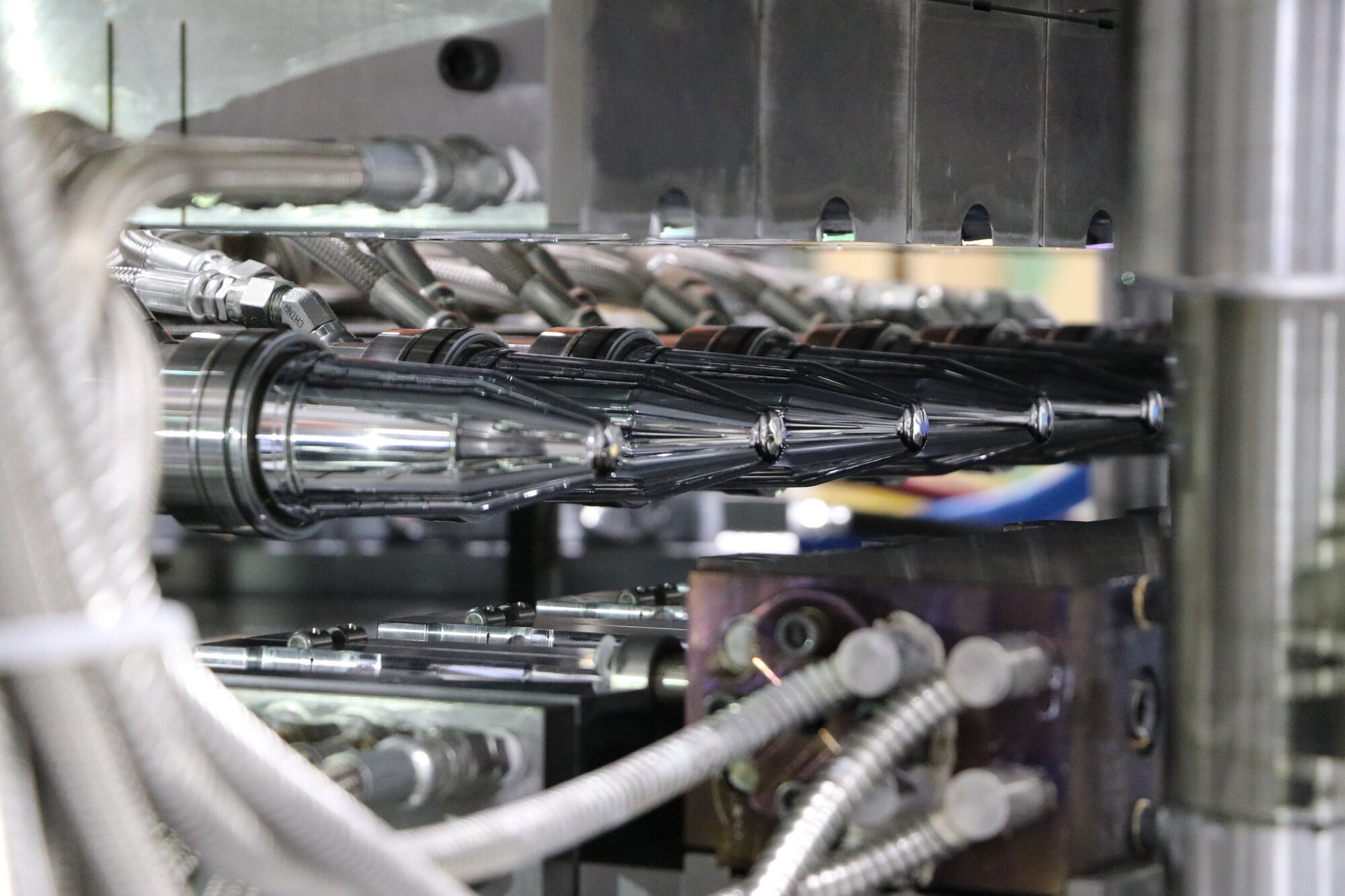

Mold Making

Cost effective, on time and great quality manufacturing that minimizes down-the-road repairs and reduces unit costs.

Mold Repair

Decades of experience and expert problem solving gets your mold back into the press quickly.

Prototyping

If you quickly need to check the form fit and function of your designs, we can 3D print your parts to give you comfort that your product will work as you envisioned it. From there, we develop prototype molds for quick production runs which will allow you to certify your product while mass production molds are being made.

Reverse Engineering

Have a part but no drawing? Allow Adler’s experienced reverse engineering team to assist in completing your design library.

Sampling

Before shipping out molds, we will sample the parts in our molding facility to reduce lead times and assure you get a mold that meets your dimensional and functional requirements.

Spare Parts

Extensive knowledge from years of mold making allows Adler to excel in making spare parts for existing molds.

Turn-Key Validation

Adler has dedicated space with the needed facilities to accommodate full turn key validations. Need to qualify a new mold without disrupting existing production? Alder has the resources to help you make this happen. Whether it is simple mold validation or all the way to a full IQ, OQ, PQ validation with auxiliary equipment and extensive inspection requirements, Adler has the engineers, facilities, and quality systems to make your qualification seamless.

Vendor Managed Inventory

We will efficiently optimize stock levels, minimize stockouts, streamline replenishment processes, and ensure timely product availability, ultimately reducing costs and improving overall supply chain performance for our customers.

We know moldsTM

©2026 ADLER INDUSTRIAL SOLUTIONS INC.

Contact Us

We want to learn more about you and how we can help.

Main Office

1008 SE Browning St.

Lee's Summit, MO 64081

We use cookies to track some on site behavior. By continuing to use this website, you consent to the use of cookies in accordance with our cookie policy.