CAPABILITIES

Full in-house manufacturing capabilities assures quality parts with on-time delivery

Utilizing the latest state of the art machining capabilities along with in-house developed quality capturing software, Adler can consistently achieve tolerances to 0.0001” (0.00254mm). Adler is not just investing into our current manufacturing needs but investing to build the mold maker of the future.

3D Part Scanning

Adler’s non-contact 3d laser scanning capabilities allow us to capture part geometry from a wide variety of

parts and assemblies used in numerous industries. Ranging from products for such industries as plastic packaging,

automotive, aerospace, industrial cooling, concrete forming, healthcare, scientific research, commercial art

production, and metal casting, with part sizes from a few inches in diameter to fan blades 14 feet long.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

CMM

Utilizing Zeiss and Mututoyo CMMs, Adler’s ensures ongoing quality by checking 100% of our parts

and capturing all data in our in-house Q-Data software.

Available from:

- R&D/Leverage

- R&D Europe

CNC Milling

Our milling department offers full 5-Axis Vertical milling along with both vertical and horizontal 3-Axis milling

allowing us to make parts large or small. Achieving sub-micron accuracies on our fleet of Yasdas with 3R robotics

or hitting 0.0001” (0.00254mm) tolerances on our Mikrons, Adler assures quality parts that are on time, every time.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

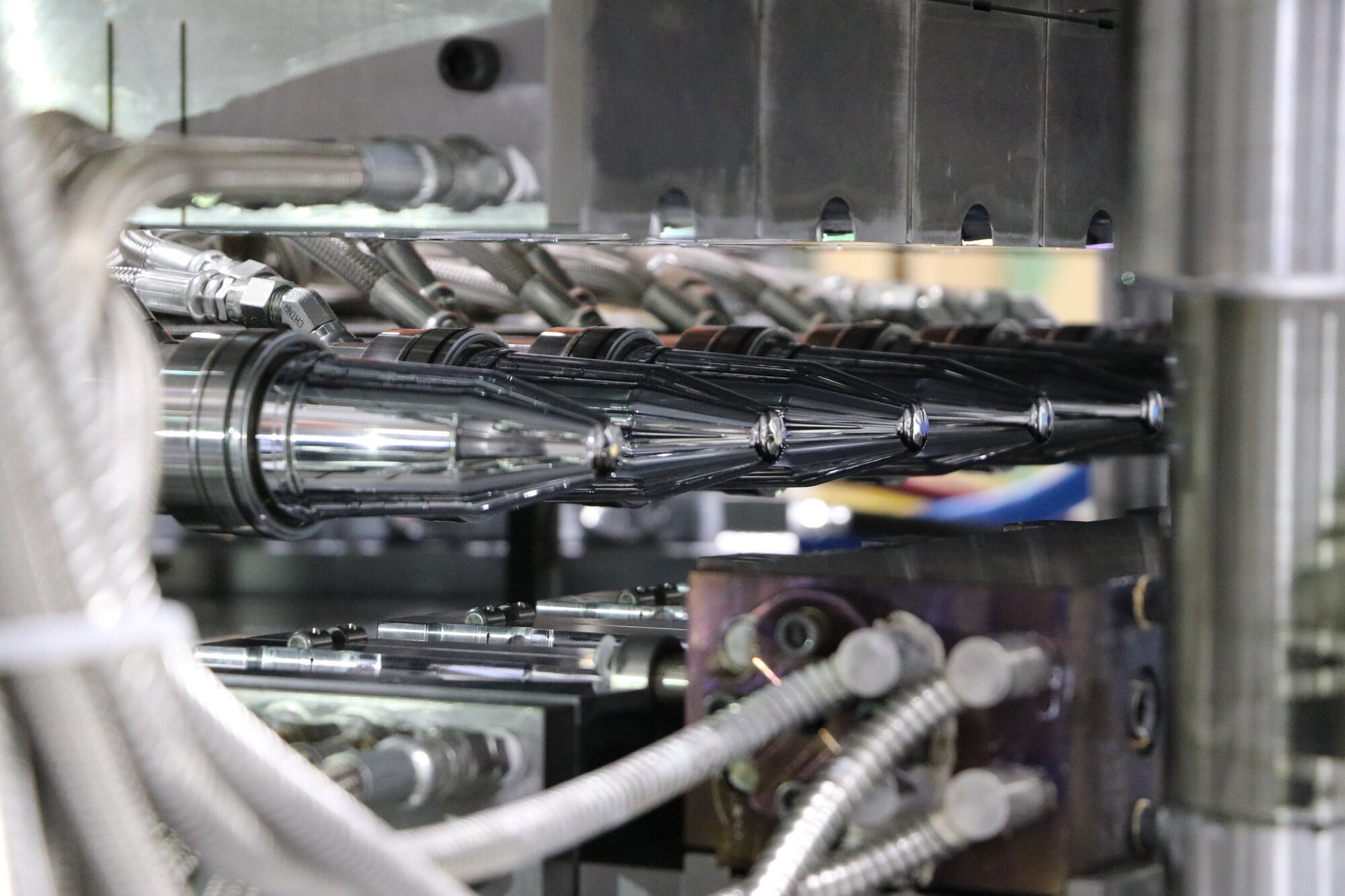

CNC Turning

With decades of experience in CNC turning, we have the capabilities to manufacture any kind of round work with our

2- and 3-axis lathes, and to hold tolerances within 3 microns. Exotic features, super tiny holes, hardness, does

not scare us by any stretch of the imagination, it is the world we have grown accustomed to, and excel at.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

Finite Element Analysis

Our technical expertise includes the use of finite element analysis (FEA). Our research team provides structural

and thermal analysis to evaluate stress, deflection, and temperature distribution. We also use mechanism dynamics

to look at stress and deflection at specific points in time during the motion of a mechanism. We also have

computational fluid dynamic software (CFD) that can analyze fluid flow.

Available from:

- R&D/Leverage

Laser Engraving

Harnessing advanced laser engraving technology, we specialize in crafting intricate and precise designs with unmatched expertise.

Our mastery in laser engraving ensures unparalleled quality and attention to detail in every project we undertake.

Entrust us with your vision, and let our skilled craftsmen transform your ideas into stunning reality through the artistry of laser engraving.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

Laser Welding

Our experienced welding team has the expertise to weld precision medical components and mold tooling from .005” welds to heavy equipment to off load cargo ships. Whether you need to fix mold components or any other type of metal application, our weld shop ensures a quality result.

Welding Process:

- Laser Welding

- Tig Welding

- Arc Welding

Materials:

- Aluminum

- Stainless Steel

- Magnesium

- Tool Steel

- Mild Steel

- Titanium

- Berrylium

Available from:

- R&D/Leverage

- R&D Europe

Mold Flow Analysis

Adler uses the full blown MPI software to evaluate mold design, molding processes, and water flow requirements for molds we build. Adler has multiple trained engineers running the software. Simulation engineers have strong backgrounds in material selection, product design, mold design, and injection mold processing allowing them to take all molding variables into account while performing simulations. We have the software and the experience needed to evaluate the simulation results and convey those results in a meaningful way to our customers.

Available from:

- R&D/Leverage

- Pinnacle Molds

- Rapid Mold Solutions

Prototype Parts

We offer multifaceted rapid prototype service focused on creating the highest quality models with the most competitive pricing in the industry. We aid in product development and market research studies to speed up Time to Market for your projects by providing Photo Quality, Shelf-Ready Prototypes for a realistic form, fit and function.

Available from:

- R&D/Leverage

- Pinnacle Molds

- Rapid Mold Solutions

Prototype/Unit Tooling

We specialize in bringing innovative concepts to life with precision and speed. Our expertise lies in crafting tailored tooling solutions tailored to the unique needs of each project, ensuring rapid prototyping and seamless production transitions. Count on us to deliver exceptional quality and efficiency in Prototype/Unit Tooling, guiding your ideas from conception to reality with unparalleled skill and dedication.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

Sinker EDM

Distinguished for our mastery in Sinker (EDM), we excel in shaping intricate components with unparalleled precision and efficiency. Harnessing advanced EDM technology, we specialize in crafting complex geometries with utmost accuracy, ensuring superior quality in every detail. Trust us to transform your designs into reality, as we leverage our expertise in Sinker EDM to deliver exceptional results that exceed your expectations.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

Tight Tolerance Round Grinding

Utilizing fully automated Kellenberger and Studer CNC

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

Tight Tolerance Surface Grinding

We specialize in achieving precision and accuracy beyond compare. With our advanced grinding techniques, we meticulously craft components to meet the most demanding specifications with utmost consistency. Count on us to deliver exceptional quality and reliability, as we leverage our proficiency in tight tolerance surface grinding to ensure flawless results that elevate your projects to new heights of excellence.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

Wire EDM

We take great pride in fabricating intricate components with precision. Through the utilization of cutting-edge technology, we excel in fabricating intricate components and meeting stringent tolerances, ensuring excellence in every aspect. Rely on our expertise in wire EDM to bring your concepts to fruition, delivering outstanding outcomes that surpass your requirements and aspirations.

Available from:

- R&D/Leverage

- R&D Europe

- Pinnacle Molds

- Rapid Mold Solutions

We know moldsTM

©2025 ADLER INDUSTRIAL SOLUTIONS INC.

Contact Us

We want to learn more about you and how we can help.

Main Office

1008 SE Browning St.

Lee's Summit, MO 64081

We use cookies to track some on site behavior. By continuing to use this website, you consent to the use of cookies in accordance with our cookie policy.