MOLD TYPES

The most comprehensive mold making capabilities in the world

Regardless of your mold type, the Adler network of mold makers have you covered. Our multiple facilities specialize in niche mold making sectors that allow Adler to offer complete product solutions to our customers for a successful, timely product launch.

2-Shot Molds

Adler’s mold build experience in 2 Shot or Multi shot molding allows our customers to achieve multi material or multi colored parts for high volume production.

- In-House 2-shot sampling capability in our Missouri facility.

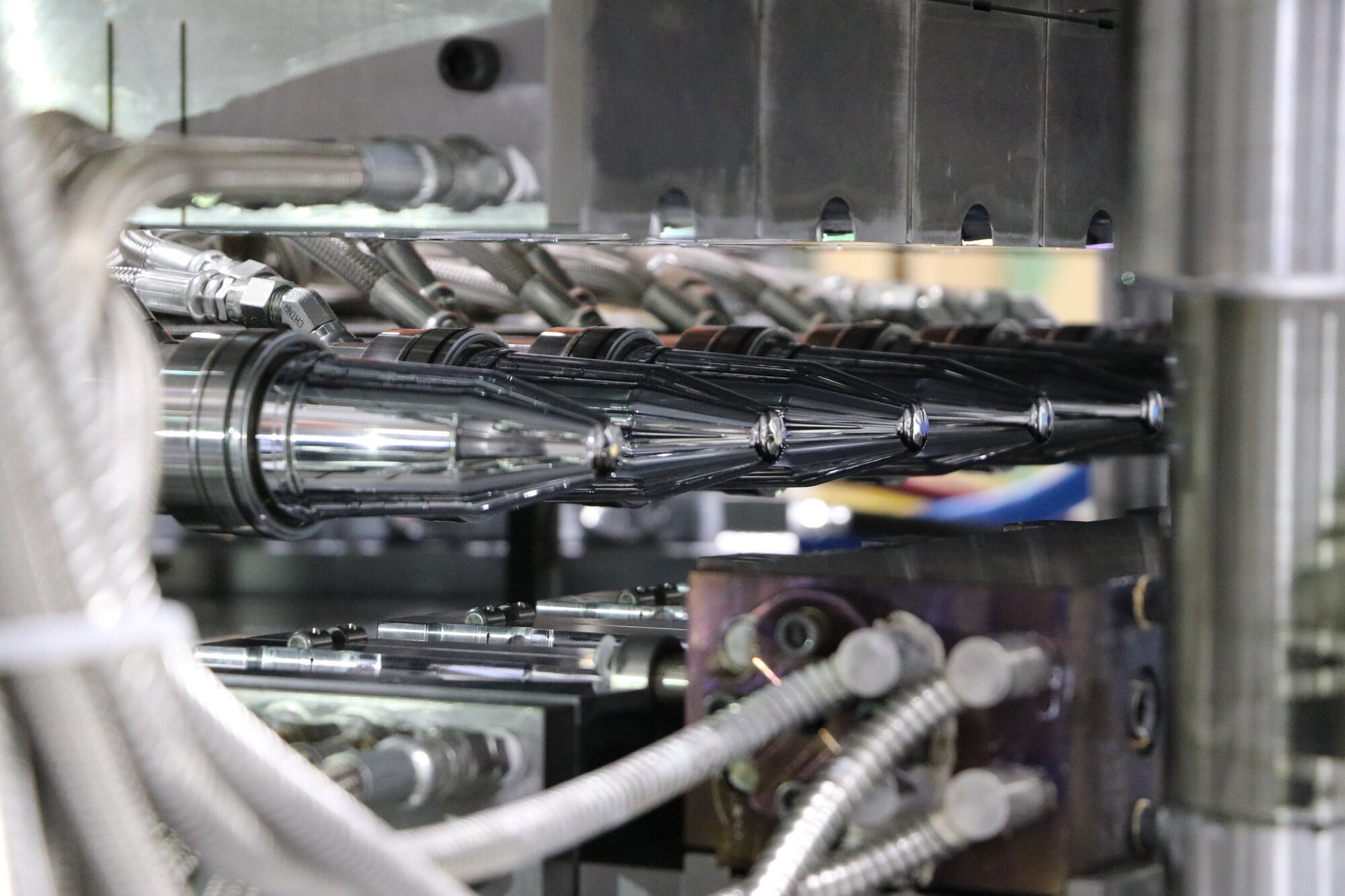

Injection Blow Molds

Quality IBM molds start with quality IBM designs. Our experienced IBM design team works hand in hand with you to ensure our molds will outperform those from any competitor. Working with tight tolerance

- Patented Genesis Manifold Technology

- In-House Sampling and Validation

- MWA Bottle and Tooling Inspection Labs

- Unit Development

Liberty IBM System

The Liberty IBM System from R&D/Leverage is a next-generation injection blow mold solution that delivers unmatched startup speed, safety, and production quality. Through patented innovations like the Genesis Hot Runner System and Self-Alignment Cavity Technology, this system simplifies mold setup, extends tool life, and dramatically improves part quality. It offers the industry's highest return on investment by reducing waste, labor, and downtime while increasing output and precision.

- Genesis Manifold System with thermally insulated nozzles and on-the-fly flow balancing

- Self-aligning injection and blow cavities mounted on precision dowels for perfect alignment

- Thermal isolation technology for broader process windows and minimized wear

- Fast, low-labor startup with fewer adjustments and no nozzle torching

- Cam Activation System for retractable blow cavity bases and easier cavity maintenance

Injection Molds

Adler is your contact for a variety of molds. Ranging from your simple open and shut cold runner system to the complex 96 cavity and above stack tools with hot runner controls. Our tool makers and Machine specialists have decades of expertise and are looking forward to every challenge that can come their way.

- Extensive expertise in direct side-gate hot runner technology with a wide range of hot runner systems.

- Complex mechanical, servo, hydraulic or pneumatic actions producing robust flash-free shut-offs.

- True Class 101, 101+, 102 molds

Injection Stretch Blow Molds

For over 40 years, our experienced ISBM team has made ISBM tools for products you’ll see on shelves day in and day out. Utilizing only the best materials, our molds are built to last ensuring your first bottle will be just as good as the 1 millionth.

- Patented Genesis Manifold Technology

- Patented Liberty System Technology

- In-House Sampling and Validation

- MWA Bottle and Tooling Inspection Labs

- Unit Development

Preform Molds

With decades of experience in servicing both the IBM and ISBM markets, Adler is the expert in the development and manufacturing of preform molds. Our in-house engineering team will provide the right mold to meet your annual demands with guaranteed cycle times.

Stack Molds

The benefits of plastic part piece pricing for stack molds is hard to compete in this modern-day market. Adler is here to help advise you on what steps your company needs to take to help achieve the competitive pricing for your product. Increase cavitation and productivity in a smaller molding machine if you have the daylight to open and eject parts and shot size to fill additional cavities. Nearly double the production at a cost much lower than 2 molds in 2 machines.

- Hot runner stack mold experience with a wide range of hot runner systems – we will your preferred hot runner supplier.

We know moldsTM

©2026 ADLER INDUSTRIAL SOLUTIONS INC.

Contact Us

We want to learn more about you and how we can help.

Main Office

1008 SE Browning St.

Lee's Summit, MO 64081

We use cookies to track some on site behavior. By continuing to use this website, you consent to the use of cookies in accordance with our cookie policy.